-

×

Queen Pillow, 60x60cm: Luxurious Comfort

1 × $99.00

Queen Pillow, 60x60cm: Luxurious Comfort

1 × $99.00 -

×

Bandage neck size 3

1 × $19.00

Bandage neck size 3

1 × $19.00 -

×

Kiev Vitamin Plant Corvalment, 0.1 g, 30 caps.

1 × $19.00

Kiev Vitamin Plant Corvalment, 0.1 g, 30 caps.

1 × $19.00 -

×

Orthopedic insoles for children. art. 26E p.13 "Effect"

1 × $19.00

Orthopedic insoles for children. art. 26E p.13 "Effect"

1 × $19.00 -

×

![Smith Frequency 086: [Relevant Keyword] Guide](https://globalhealingweb.com/wp-content/uploads/2024/11/6295017024-247x296.jpg) Smith Frequency 086: [Relevant Keyword] Guide

2 × $139.00

Smith Frequency 086: [Relevant Keyword] Guide

2 × $139.00 -

×

MIC Angrimax, 20 caps.

1 × $19.00

MIC Angrimax, 20 caps.

1 × $19.00 -

×

Elastic knee pad size 1 model 0802

1 × $19.00

Elastic knee pad size 1 model 0802

1 × $19.00 -

×

Orthopedic insoles -1B r.19 (combined)

1 × $19.00

Orthopedic insoles -1B r.19 (combined)

1 × $19.00 -

×

55mm Ashless Filter Papers, White Ribbon, 100 Count

1 × $9.00

55mm Ashless Filter Papers, White Ribbon, 100 Count

1 × $9.00 -

×

MIC Troxerutin-Mick, 200 mg, 50 caps.

1 × $29.00

MIC Troxerutin-Mick, 200 mg, 50 caps.

1 × $29.00 -

×

VEYLE ERGO Memory Foam Pillow: Anatomical Support (39x59x10cm)

1 × $79.00

VEYLE ERGO Memory Foam Pillow: Anatomical Support (39x59x10cm)

1 × $79.00 -

×

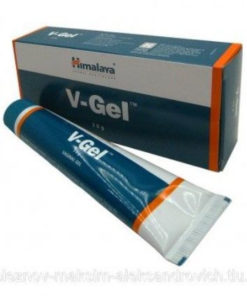

V-Gel Vaginal Gel (2 x 30g)

1 × $19.00

V-Gel Vaginal Gel (2 x 30g)

1 × $19.00

Subtotal: $627.00

Free worldwide shipping on orders $99+

Free worldwide shipping on orders $99+

US: 2–3 weeks,

US: 2–3 weeks,

EU: 1–2 weeks,

EU: 1–2 weeks,

Worldwide: 1–4 weeks

Worldwide: 1–4 weeks